> Sichuan Rongzeng Environmental Protection Technology Co., LTD., committed to the R&D, promotion and service of environmental protection technology, is an environmental protection company committed to the recycling and reuse of waste organic solvents, mainly providing the recycling of hazardous waste services.

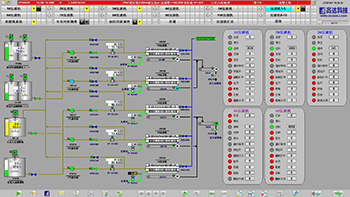

> The project includes 6 organic waste liquid production and treatment lines and its public supporting works provides users with configuration and control solutions for multiple key process equipment.

> This project, invested and constructed by Hanzhong Shimen Hazardous Waste Collection & Disposal Center, adopts rotary kiln incineration technology as hazardous waste incineration main device, which daily treatment capacity of 50 tons and processing capacity of 17,000 t/a. The project is generally contracted by New Zhongtian Engineering Technology (Chongqing) Co., Ltd., and we complete the electrical automatic control system equipment (instrument, DCS, SIS, industrial TV, cable, bridge, auxiliary materials, construction).

> Jingjin Environmental Protection Co.,Ltd. is a comprehensive environmental protection service provider integrating filtration equipment manufacturing, overall solution of filtration technology, general contracting and operation of environmental protection projects. It is the vice president unit of China Environmental Protection Industry Association, and the main drafter of the national standard of filter press. Its products are exported to 123 countries and regions.

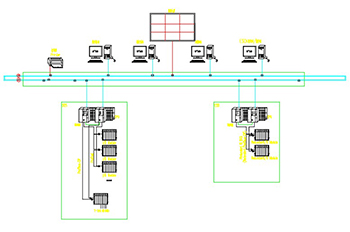

> Gaoda is parter for this project, the general contract of the two sludge treatment projects of Yueyang Forest & Paper Co., Ltd., and responsible for the DCSpart of the two of projects.